Wire Bonding

Wire Bonding

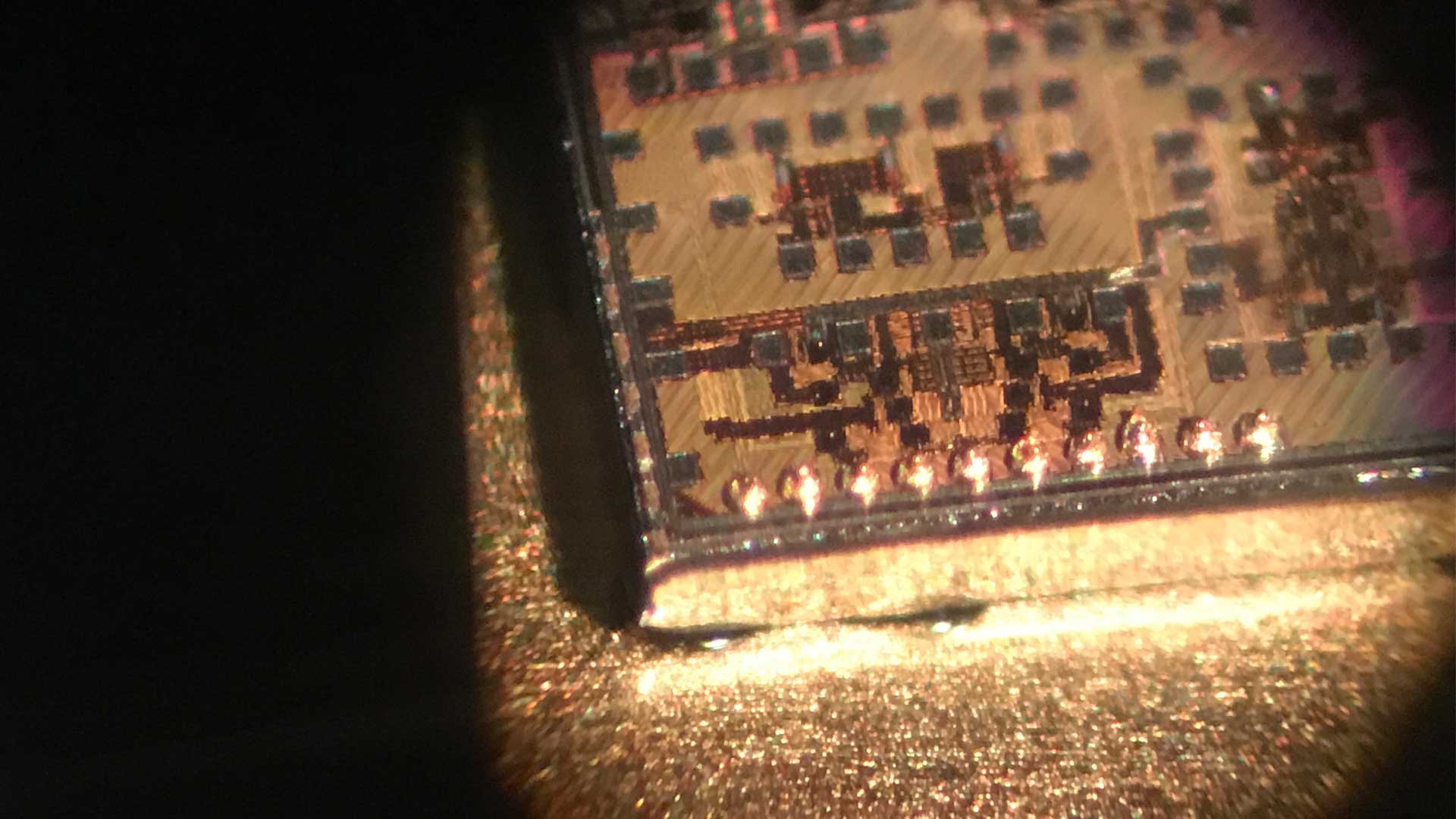

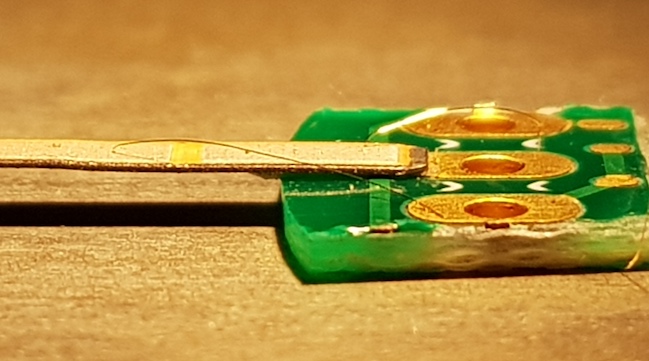

Wire bonding is a technique used to create interconnections, or stud bumps in electronics. It is most commonly used to connect an integrated circuit (IC) or chip to a package, but can also be used to connect die to other components or even a Printed Circuit Board (PCB). It is the most widely used interconnect technology due to its flexibility and cost-effectiveness.

Examples

Wedge BondingWedge bonding is usually performed at ambient temperature using pressure and ultrasonic energy to form the wire bonds. It is most often used with aluminium bond wire to bond to aluminium (Al) or gold (Au) bond pads. It is possible to wedge bond with gold wire using a special tool. The advantage of Al wedge bonding is that it is less susceptible to contamination than other forms of wire bonding. The disadvantage is that it is more likely to cause cratering where damage occurs to the semiconductor below the bond pad. |  |

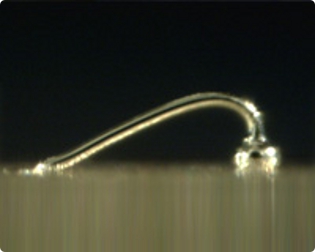

Ball BondingBall bonding is usually performed using a combination of temperature, pressure and ultrasonic energy to form the wire bonds. It is most often used with gold bond wire but many metals can be used depending on the application. Automatic ball bonding is the quickest form of wire bonding as it is not limited, like wedge bonding, to having the wire loop made in as straight a line as possible with the initial bond so reduces die movements. It is less prone to cratering where damage occurs to the semiconductor below the bond pad but has the disadvantage of heating the die. |  |

Gold stud bumpingThe gold ball bumping process creates conductive gold balls or stud bumps on the die bond pads. Gold stud bumping is a process used with die attach methods including flip chip bonding. The ball size depends on bonding wire size, the length of the tail (the wire used to make the ball) and the electronic flame off (EFO) power used to create the ball. | |

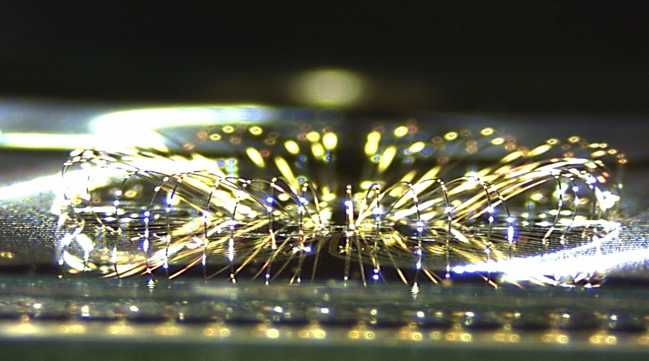

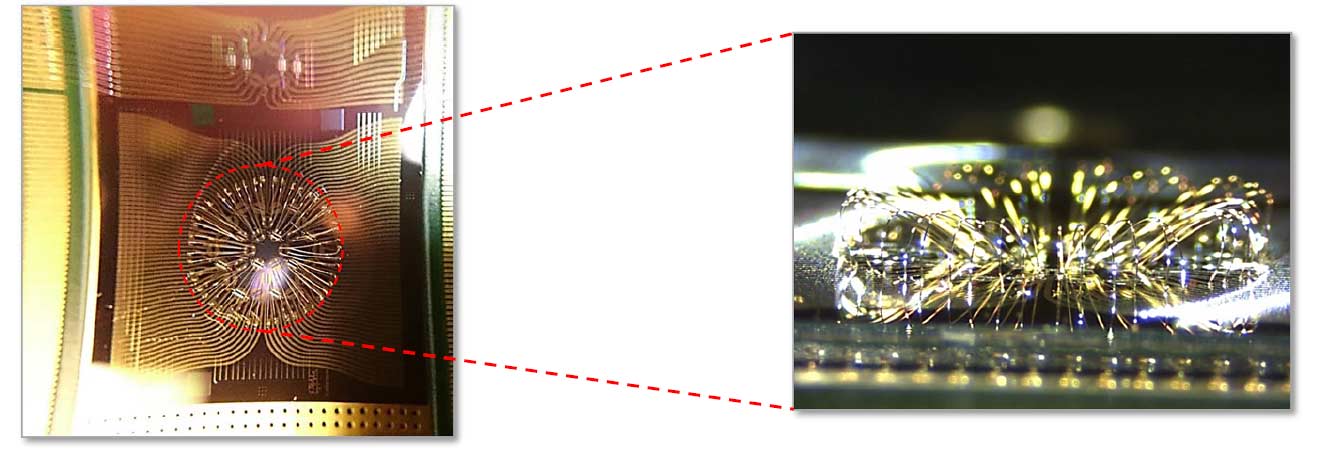

Advanced TechniquesAdvanced wire bonding techniques are based on varying bonding parameters and routines to achieve additional specific features on the bonds such as a security ball on the 2nd bond and various loop shapes. |

Wire Bonding At Our Facility |