Quality

Quality Assessment

Quality assessment of a packaging process is often subjective to the function and operating conditions of the electronic components. This ensures that the assessment produces an accurate reflection of the real life load on the packaged assembly. The key rule of characterising packaging processes is to design tests which will produce the most failure modes of interest. The assessment process also includes ageing characterisation which deals with the quality of packaging after the individual process or complete packaging has gone through a number loading/unloading cycles. This may include thermal, mechanical and pressure loads designed to replicate real life loading cycles.

Die Attach QualityDie attach failure mechanisms include physical failure of the die bond, physical damage to the die including its surface and adhesive contamination on the die surface. |  |

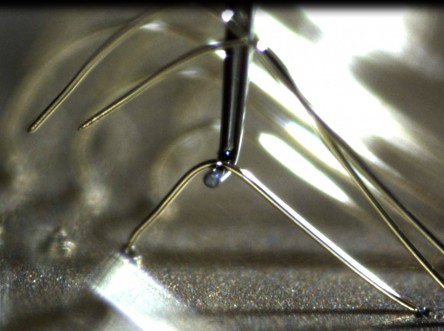

Wire Bonding QualityA wire bond should be strong enough to withstand application specific mechanical and thermal stresses without breaking. Bond strength is an indication of quality and reliability of a wire bond. |  |

Encapsulation QualityThe purpose of encapsulation is the protection of die and wire bond assembly, or components on a substrate such as a PCB board. The encapsulation failure mechanisms are usually physical defects in the encapsulation which expose the die/wire bonds to the environment. |  |

A variety of methods can be used for characterising packaging processes such as microscopic inspection, surface profiling, dedicated mechanical tests, thermal testing and environmental testing. These methods can be used individually or in combination to achieve a comprehensive assessment; the choice of methods depend on the failure modes of interest. The characterisation tests may be carried out for each individual process or for the whole assembly after packaging. In addition to the assessment, using best practices to avoid known issues in the packaging processes also improves packaging quality. The three main packaging processes, die attach, wire bonding and encapsulation have standard characterisation tests for quality assessment. Bond strength is the mechanical strength of a bond that indicates bond quality and reliability.

Quality Assessment at our Facility

The Advanced Packaging Facility has a range of testing and characterisation equipment. This includes Nordson DAGE 4000 bond tester, Alicona infinite focus non-contact surface profiler, Tencor P-11 contact profiler, Zeiss EVO scanning electron microscope and Weiss environmental chamber. We aim to replicate the load stresses on a package in every quality assessment to ensure meaningful characterisation of the packaging process and directly relevant results to the operating conditions.