Encapsulation

Encapsulation

Encapsulation is the process of encasing a die which has been die and wire bonded in a protective coating. The purpose of encapsulation is to protect the semiconductor die and its wire bonds from its operating environment. The potential sources of damage to dies include moisture, dust, dirt, solvents, mechanical straining and scratching. An encapsulation deposition can consist of epoxy, sealants and additives individually or in combination with each other.

Examples

PreparationThe process of encapsulation requires a systematic preparation as a prerequisite. Preparation is mainly focused on application based material selection, material management and material conditioning. |  |

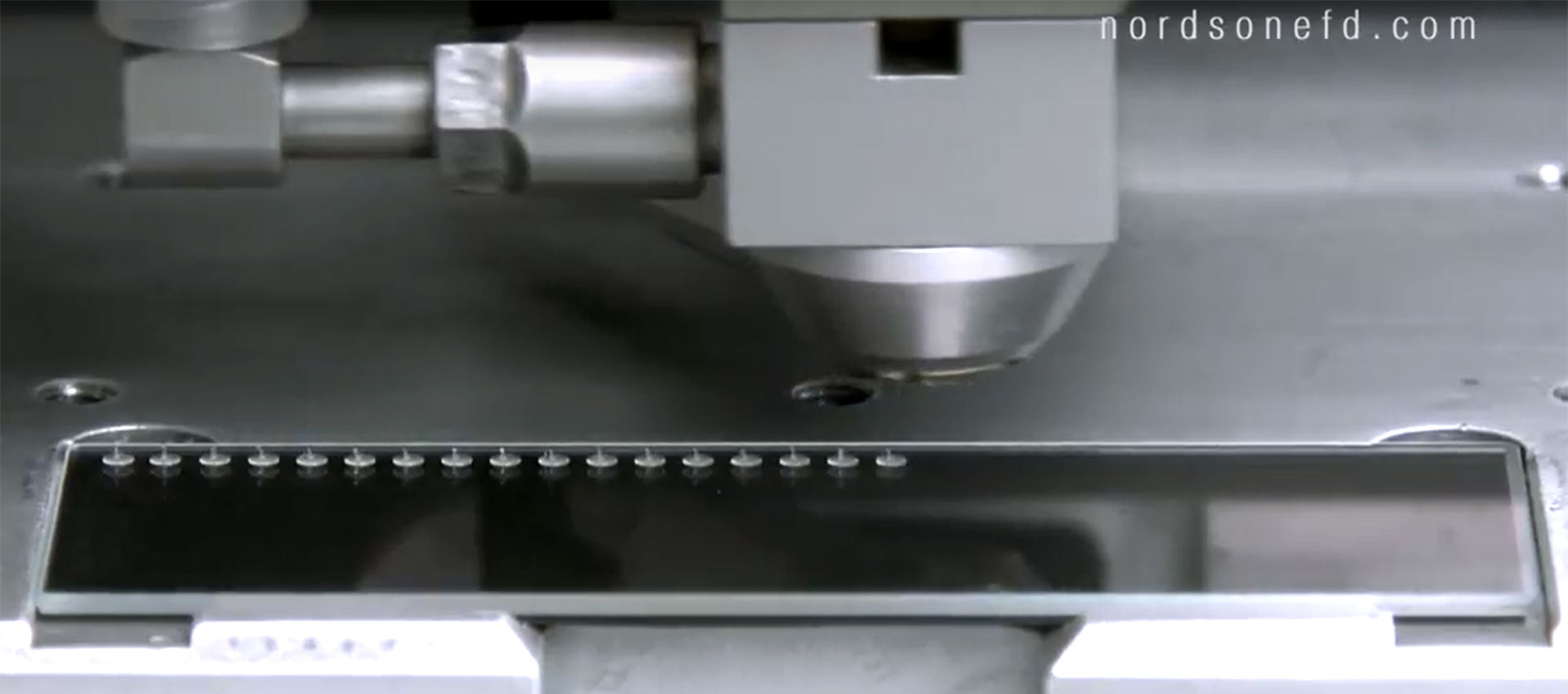

DispensingDispensing is a direct-write process for additively depositing a material on a substrate. It is typically used for depositing materials for the encapsulation process. It can deposit controlled quantities of materials in precise locations on a substrate. It offers a complete freedom of design where a material can be deposited in any pattern. It is a drop on demand repeatable process which can achieve consistent results with minimum material wastage. | |

JettingJetting or non-contact dispensing is an additive process where a material is deposited by rapidly shooting it at a substrate without making any physical contact. Like dispensing, it is a drop on demand process which produces consistent results and minimum material wastage. It is a versatile process which allows device designers to make advanced package designs for smaller products as the encapsulant can be deposited without the need for a nozzle to physically move close to the components. |  |

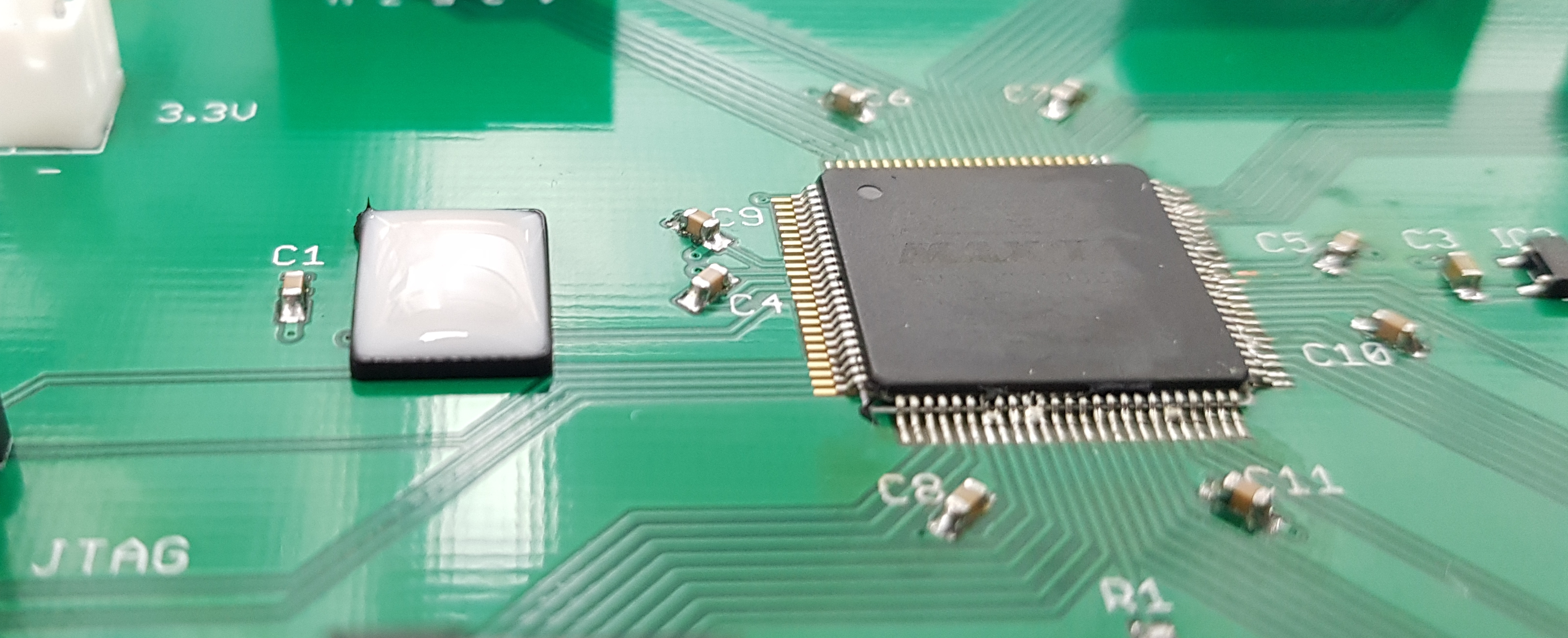

Conformal CoatingsConformal coatings are used for protecting electronic assemblies from their environment such as moisture, dust, chemicals and mechanical abrasion. They are thin films which conform to the surface topography of an electronic assembly such as components attached to a PCB board or a die attached to a package. Materials commonly used for conformal coatings include acrylics, silicones, urethanes, PTFE and parylene. |  |

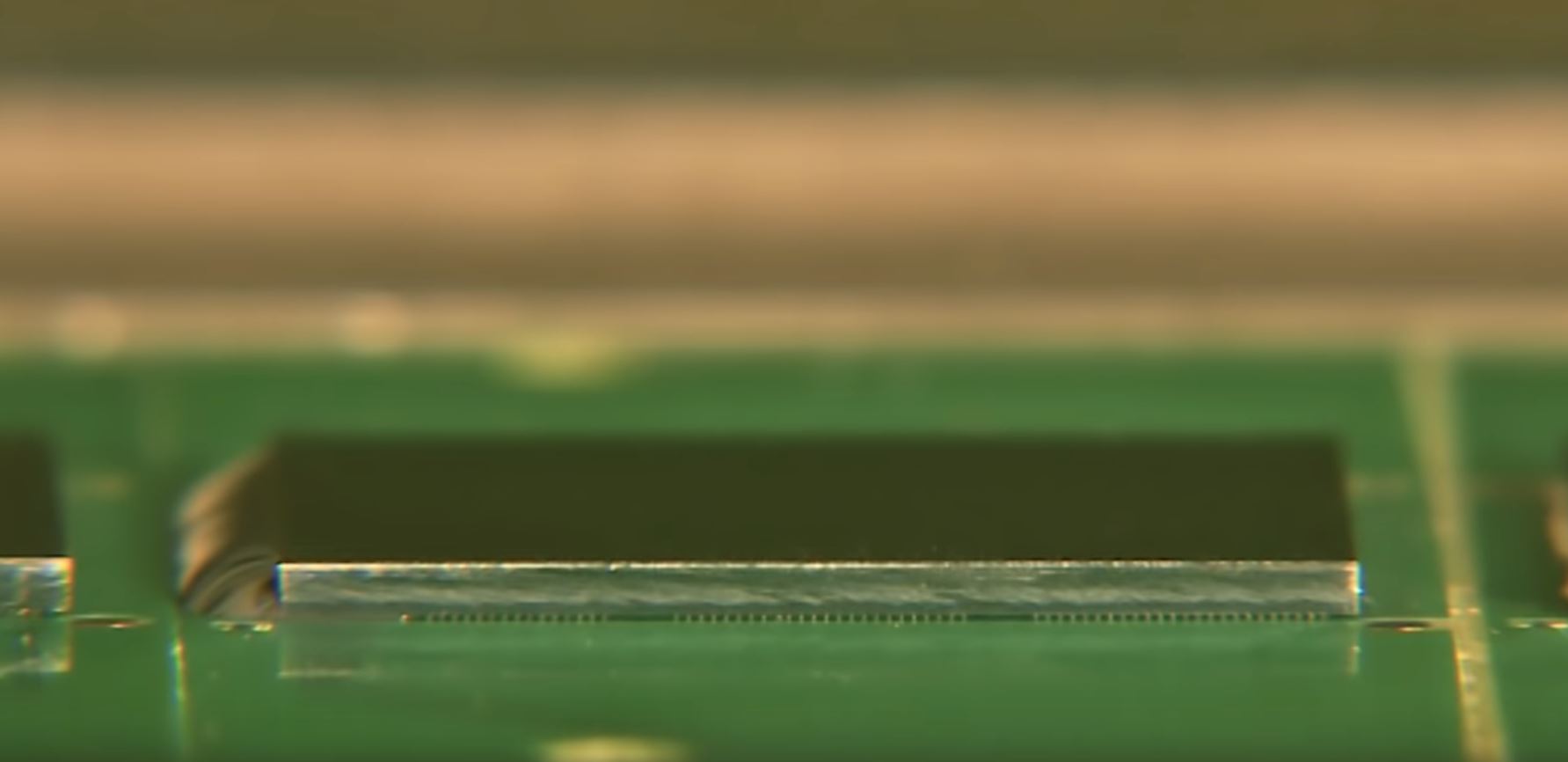

UnderfillUnderfill is the process of encapsulating the flip chip assembly to improve its durability and reliability. An encapsulant is deposited in the gap between two dies or a die and the substrate making the physical contact and the electrical interconnections more reliable. |  |

CuringThe final part of an encapsulation process is curing which ensures the encapsulant is permanently settled, achieves all of its physical and chemical protective properties. The curing requirements of an encapsulant are formulation specific. |  |

Encapsulation Types

Glob tops are achieved by either dispensing one material in a hemispherical shape or by dispensing two materials in a dam and fill configuration. One material is dispensed first to form the walls of a dam and another material fills the dam. The material used for dispensing walls is normally a higher viscosity material than the one used for filling the dam. The higher viscosity material traps the low viscosity material in the walls and allows the low viscosity deposition to attain the required thickness. They are commonly used for sealing LEDs.

Conformal coatings are useful for protecting electronic components on a substrate, typically a PCB, from its environment such as moisture or solvents. They can be achieved by dispensing an encapsulating material on a target component to completely cover the target. Various materials with different protective properties can be used to conformal coat a component.

Underfill is the process of encapsulating the electrical interconnections between two dies. The encapsulant is deposited around the edges of two dies. The encapsulant flows through the gap by capillary action.

Encapsulation At Our Facility |