Advanced Techniques

Advanced Wire Bonding Techniques

Advanced wire bonding techniques include security ball bonding, wire loop forming, and stitch bonding.

Security Ball BondingFor additional reliability of the wire bond a security bond over the stitch or second bond of each ball bonded wire is added. | |

Wire Bond Loop FormingSome applications require different loop shapes to be formed as part of the wire bond process. To create the desired loop suitable Loop Parameters are adjusted to form different shapes which lead to different characteristics of the bond, for example increasing its stability. The different loop shapes are formed by creating a more complex program of steps in the path of the capillary, performing that path determines the final loop shape. | |

Stitch BondingSome applications require several bond pad sites to be joined together. |

Control of wire loop formation is important in wire bonding for many of the special microelectronic packages available. Complex loop shapes can significantly slow down the throughput of bonding devices and the lifetime reliability of the wire bond and yield of manufactured devices.

Wire Bond Loop Types

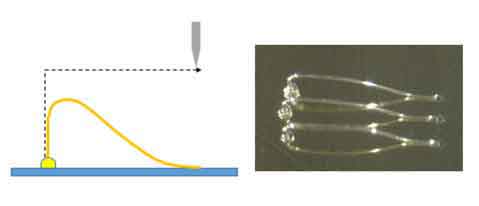

The capillary moves up and towards the second bond site. The longer the wire loop the tension between the initial wire bond and the wire increases, as does the angle of the bond wire to the bond, which can result in failures and poor stability of the wire loop.

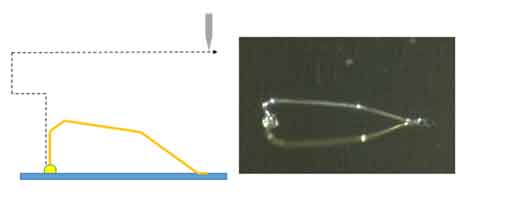

The capillary is moved away from the second bond site before it reaches the desired height. The bond wire forms a more stable shape, the angle of the bond wire to the bond is reduced and longer wire loops can be formed without losing reliability and loop stability.

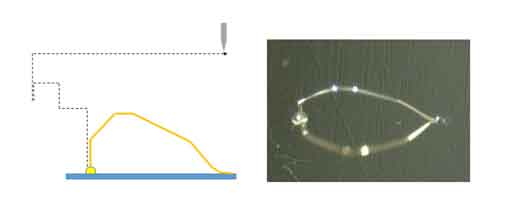

The capillary moves another 3 steps to make a double reverse loop with a more curved shape. It is very stable loop and further lowers the tension between the bond and the bond wire.

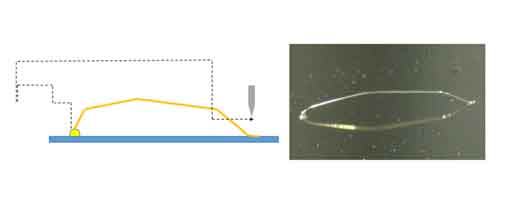

At the end of the loop forming, the capillary is moved down and towards the second bond site. This makes a long and flat loop with added angles to provide stability to the loop. Increasing parameters make to wire loop longer and flatter but increases tension between the wire bond and the wire.

Advanced Wire Bonding Techniques at our Facility

Complex wire bond loops may be required to avoid contact between the wire bond, the die and the package or to create unique 3D stacking of die where overhanging die require unique wire loop pattern development.