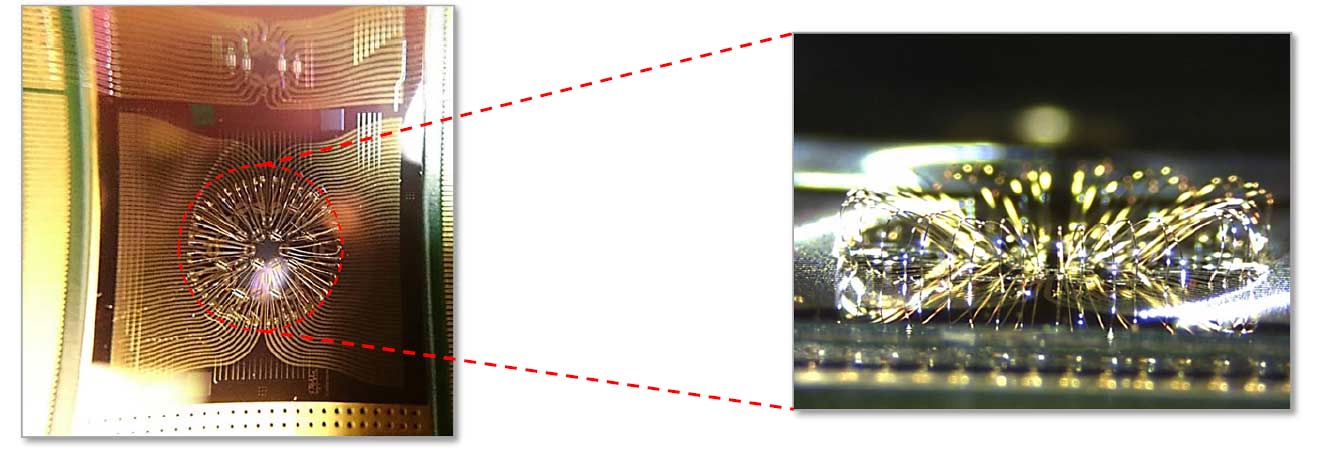

Aluminium Wedge Bonding

Aluminium Wedge Bonding

Wedge bonding is usually performed at ambient temperature using pressure and ultrasonic energy to form the wire bonds. It is most often used with aluminium bond wire to bond to aluminium (Al) or gold (Au) bond pads. It is possible to wedge bond with gold wire using a special tool. The advantage of Al wedge bonding is that it is less susceptible to contamination than other forms of wire bonding. The disadvantage is that it is more likely to cause cratering where damage occurs to the semiconductor below the bond pad.

Examples

Aluminium Wedge Bonding Work Flow

1st Bond

A wire bond wedge tool holds the bond wire and positions it onto the bond pad of the die, package or board. The wedge tool presses the bond wire onto the bonding surface and ultrasonic energy is applied for a preset time to form the bond depending on bond conditions such as bond wire, bond pad construction, etc.

For packaging applications, wedge bonding is often used where several die and bond pads need to be joined together using a technique called stitch bonding. Wedge bonding may also be preferred where long low profile loops are required. The low temperature at which wedge bonding is undertaken means it has uses where either die or package would suffer if heated. Thick wires are used to connect power devices where high currents are needed.

Aluminium Wedge Bonding at our Facility |