Wire Bonding on a Flexible Multi-Layered Printed Cantilever

Wire Bonding on a Flexible Multi-Layered Printed Cantilever

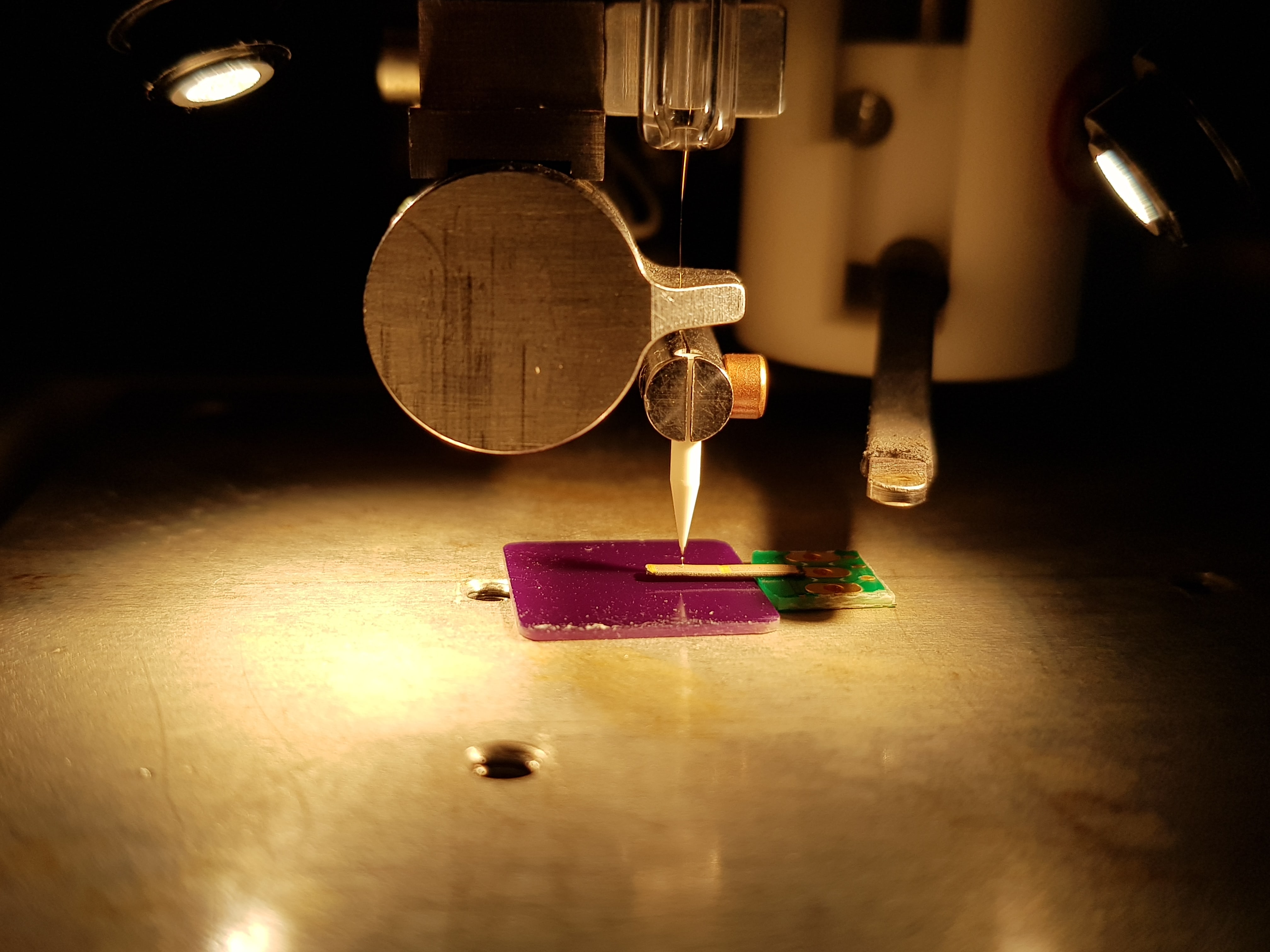

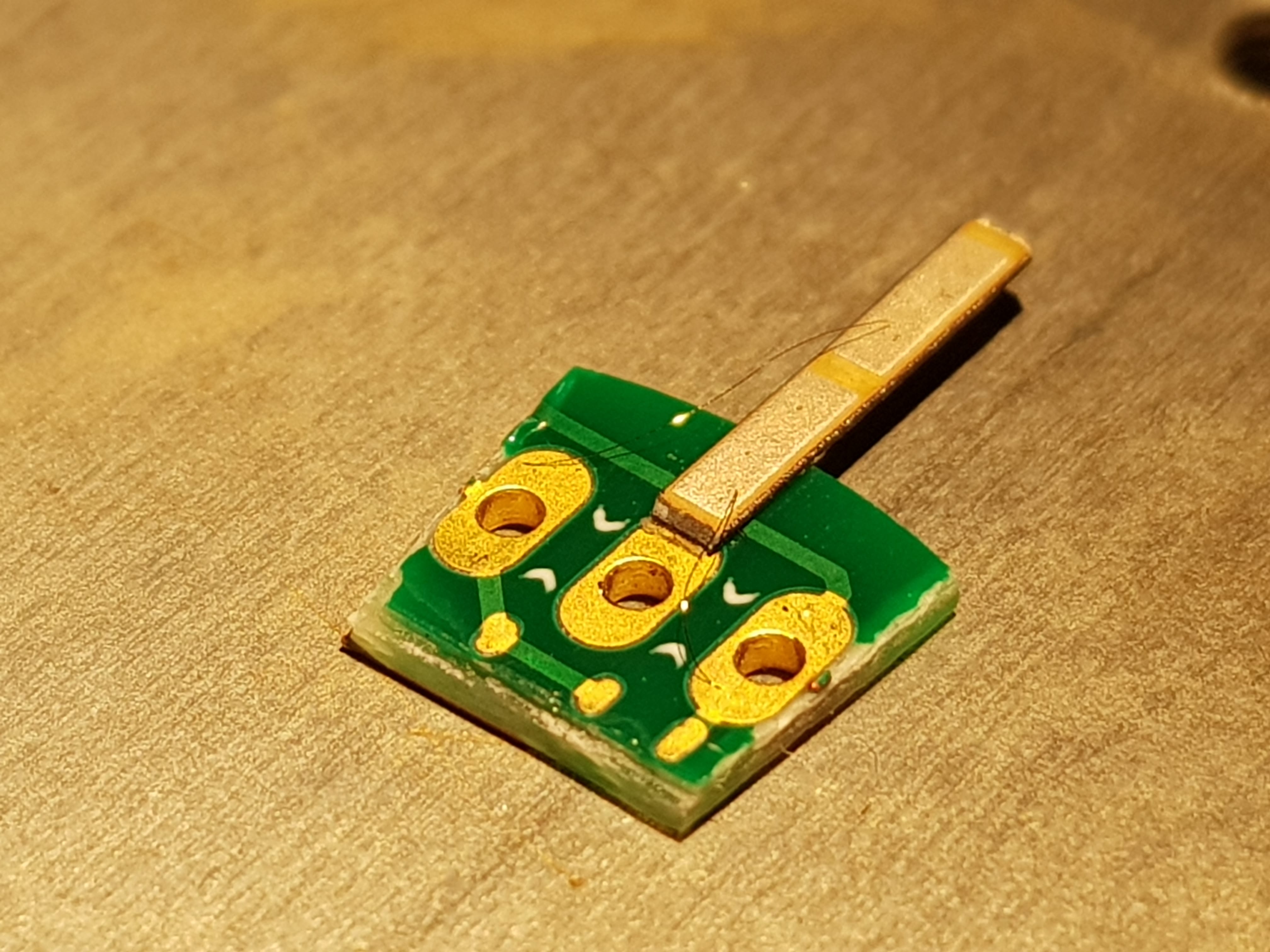

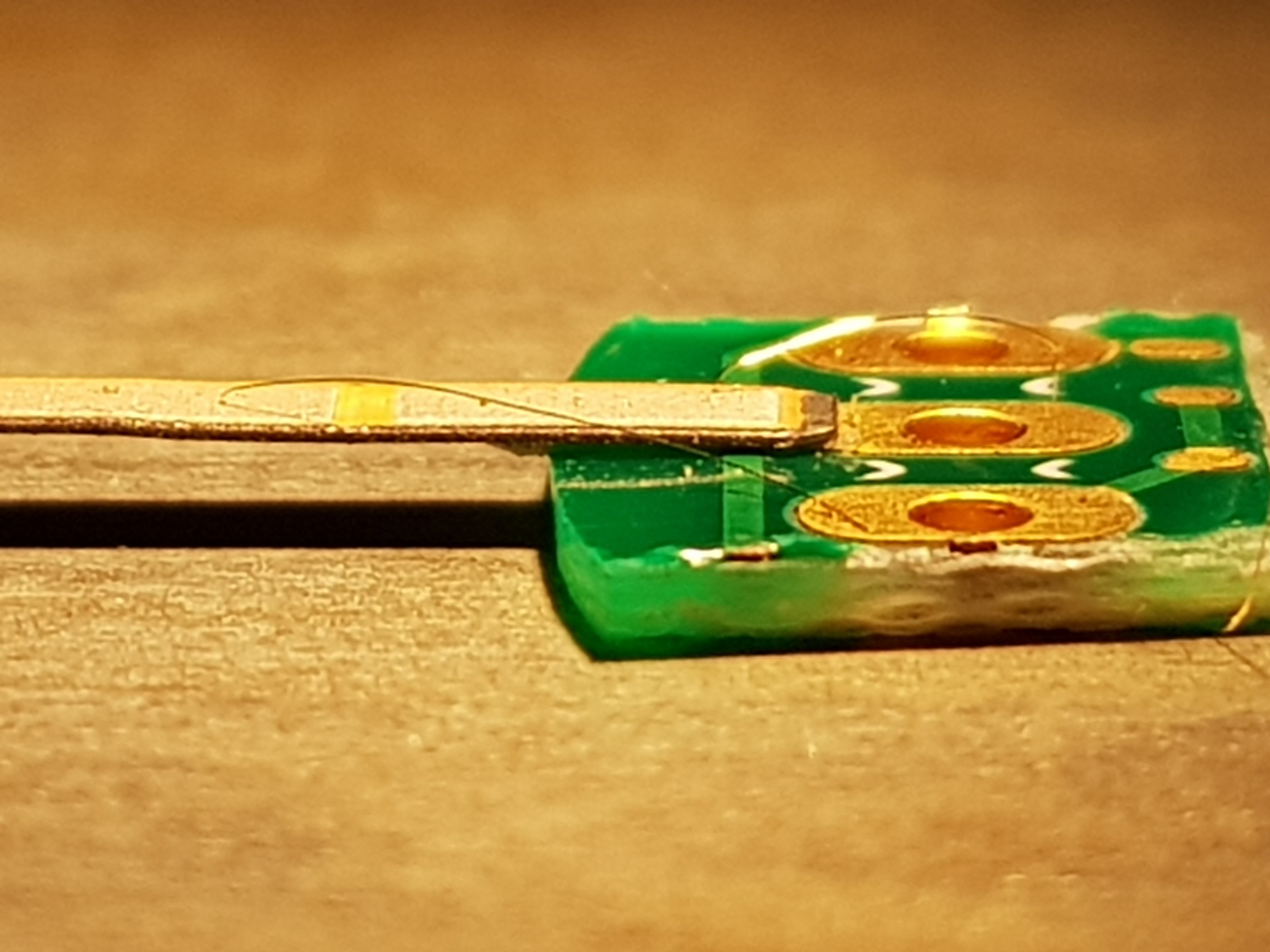

A challenging wire bonding project was wire bonding a printed cantilever structure. The cantilever was fabricated on a thin flexible stainless steel substrate, sandwiching an active layer between two printed conductors. The top conductor was divided into two parts to improve control of the active layer. The wire bonds were required to connect the two parts of the top conductor with two different gold pads. The cantilever was attached to the PCB using a conductive adhesive.

The main challenges in this project were to wire bond to printed layers and to a flexible substrate. The printed conductors consist of metal particles in a glass based ceramic binder unlike the continuous metal deposition on a die. This makes it difficult to achieve reliable intermetallic bonds or to make the wire stick to the printed layer. Wire bonding uses a combination of temperature, ultrasonic energy and mechanical force to achieve interconnections. If a bond is being made to a flexible structure two out of the three parameters, ultrasonic energy and mechanical force, can become less effective. This translates into weak intermetallic bonds or the bonds not sticking to the pads.

These challenges were overcome by first placing a raised inflexible platform underneath the cantilever during the bonding process to physically and mechanically support the flexible structure. A detailed design of experiments was then carried out to optimise the combination of temperature, ultrasonic energy, mechanical force and the time duration the force is applied to the surface. It was found that a temperature higher than 65°C was making the printed layer prone to cratering. It was also found that the printed layers required a higher mechanical force than the bond pad on the PCB for wire bonding. For this application, success was achieved by bonding to the printed layers using the gold ball bond and to reinforce the wedge bond (2nd bond) with a security ball.