Types of Packaging

Traditional Package Assembly

The die is placed in a die package traditionally consisting of metal, ceramic or plastic casing depending on the application. Package choice depends on issues such as the necessary heat dissipation, cost, reliability and operating environmental conditions of the device.

Chip on Board (COB)

The die is bonded directly to a substrate or a circuit board eliminating the time and cost to mount the die in a package first. The attached and wire bonded die needs to be protected with encapsulation. It is commonly used for LED manufacture, automotive and low cost electronics production. It is also used in aerospace where weight of the packaging is also a concern.

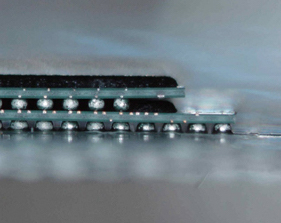

3D Integration with Stacked Dies:

The die is attached directly to another die or a series of dies to create stacked structures. Stacked structures reduce the amount of space the chips occupy and allow more electronic functionality to be included in a limited space.

System/Package in Package (SiP/PiP)

More than one die or discrete component is placed into the same package to allow multiple components to form a sub-system within a single package.